|

Gelwell's dedicated research and proven field testing of the coating products and processes enabled us to offer a wide range of anti-fog, scratch resistant, antifouling and lubricious coating technologies to meet a multitude of applications that are second to none in performance and longevity:

Anti-fog Coating

Scratch Resistance Coating

Hydrophobic Easy

cleaning Coating

Hydrophobic Drag Reduction Coating

UV Type Anti-fog

Coating

|

Anti-fog Coating

AFC SW6M

Designed

for water proof anti-fog performance for

motorcycle visors,

safety spectacles, snow

vehicles, ski visors,

optical

lenses,

water sports and athletic goggles, etc.

|

|

1.

Water proof anti-fog

performance

with

excellent scratch

resistance

2. Increase light transmission

of polycarbonate from 88-89% up to 90-91% that makes the spectacle shiny and crystal clear

3. High refractive index (> 1.53)

reduces rainbow like refraction on the spectacles and enhances esthetic appearances

4. Excellent impact resistance (up to 400 ft/sec steel ball impact resistance)

5. One component system is easy to operate for consistent high quality output that increases throughput and reduces capital, labor, utility and operational costs

6.

Water based system

is not only

environmental friendly

but also

non-invasive toward

PC

|

AFC-133P12G*:

For excellent anti-fog performance for safety spectacles, paint ball protective shields, face shield of fire prevention

and high temperature environment applications, medical goggles, etc.

|

|

1.

Excellent anti-fog performance

and scratch resistance

2. Increase light transmission

of polycarbonate from 88-89% up to 90-92% that makes the spectacle shiny and crystal clear

3. High refractive index (> 1.53)

reduces rainbow like refraction on the spectacles and enhances esthetic appearances

4. Excellent impact resistance (up to 400 ft/sec steel ball impact resistance)

5. One component system is easy to operate for consistent high quality output that increases throughput and reduces capital, labor, utility and operational costs

6. No white mist leaching in high humidity environment - the anti-fog coated spectacles is radiant, clear and transparent even in the rainy days

7. Water based system is environmentally friendly and non-invasive to substrates

|

|

AFC-GW:

ASTM 659 Certified Anti-fog Performance for Ski Goggles

& EN168 N Mark Certified Resistance against Fog and EN166 K Mark Certified Resistance against Fine Particles,Designed for water proof anti-fog performance for motorcycle visors, safety spectacles, snow vehicles, ski visors, optical lenses, water sports and athletic goggles, etc.

|

|

1. Water proof anti-fog performance

with excellent scratch resistance

2. High refractive index

(> 1.53) reduces rainbow like refraction on the spectacles and enhances esthetic appearances

3. Increase polycarbonate light transmission

from 88-89% up to 90-91% that make the substrate crystal clear and shiny

4. Excellent impact resistance (up to 650 ft/sec steel ball impact resistance for military applications)

5. Can be electroplated for sunglass applications.

6. One component system is easy to operate for consistent high quality output that increases throughput and reduces capital, labor, utility and operational costs

7. Water based system is not only

environmental friendly but also non-invasive toward PC

|

|

AFC-G*NK:

EN168 N Mark Certified Resistance against Fog and EN166 K Mark Certified Resistance against Fine Particles,Designed for water proof anti-fog performance for motorcycle visors, safety spectacles, snow vehicles, ski visors, optical lenses, water sports and athletic goggles, etc.

|

|

1.

Water proof anti-fog performance

with excellent scratch resistance

2. High refractive index

(> 1.53) reduces rainbow like refraction on the spectacles and enhances esthetic appearances

3. Increase polycarbonate light transmission

from 88-89% up to 90-91% that make the substrate crystal clear and shiny

4. Excellent impact resistance (up to 650 ft/sec steel ball impact resistance for military applications)

5. Can be electroplated for sunglass applications.

6. One component system is easy to operate for consistent high quality output that increases throughput and reduces capital, labor, utility and operational costs

7. Water based system is not only

environmental friendly but also non-invasive toward PC

|

GTA-404W2

GTA-404W2

is

designed for PC swimming goggles

|

1.

Water proof application

lasts more than 5 days

in 700ppm chlorinated

water immersion

without losing anti-fog

performance.

2.

One component system

is easy to operate for

consistent high quality

output that increases

throughput and reduces

capital, labor, utility

and operational costs

3.

No white mist leaching

even at rainy or very

hot and humid

environments.

4.

Water based system

is not only

environmental friendly

but also non-invasive

toward PC |

|

GTA-420

GTA-420 is designed for PC swimming goggles and

EN168 N-Mark Certified Resistance against

Fog

|

1.

Water proof application

lasts more than 5 days

in 700ppm chlorinated

water immersion

without losing anti-fog

performance.

2.

One component system

is easy to operate for

consistent high quality

output that increases

throughput and reduces

capital, labor, utility

and operational costs

3.

No white mist leaching

even at rainy or very

hot and humid

environments.

4.

Water based system

is not only

environmental friendly

but also non-invasive

toward PC |

AFC GAO

For Glass

Diving Goggles.

|

|

1.

One component system

is easy to operate for

consistent high quality

output that increases

throughput and

reduces capital, labor,

utility and operational

costs |

2.

Water proof application

lasts more than 5 days

in 700ppm chlorinated

water immersion

without

losing

anti-fog performance. |

TOP-5

For anti-droplet applications in automobile headlamp.

|

|

1. Excellent anti-droplet/anti-condensation performance

|

|

2. Environment friendly, Non-hazardous material, Recyclable |

|

3. Spray coating |

|

Hydrophilic Drag Reduction Coating

S-168-Ⅲ

The hydrophilic lubricious coating S-168Ⅲ is designed to reduce water friction 7 - 14% depends on the size and speed of the water vehicle. Excellent drag reduction is demonstrated on canoe, sail boat, fishing boat, small yacht, water ski and surfing applications. S-168Ⅲ coating enhances the acceleration and maneuvering capability of the water vehicle tremendously under the laminar flow condition (moving vehicle with the speed less than a few knots). The coating helps many athletes won awards in the sail boat, water ski and surfing contests in the US, Asia, Australia and New Zealand. It is simple to apply the coating on the surfing board or the ship bottom. Just paint/spray/flow S-168Ⅲ on the substrate surface and allow air dry for a few hours before getting into water.

|

Scratch Resistance Coating

RHC-101K

RHC 101K is a

water based coating solution for

providing permanent scratch resistance

properties to plastics such as

Polycarbonates.

It is very stable, non-yellowing

under heat and its chemical resistance

is excellent.

It can be electroplated with

beautiful colors to enhance the stylish

glasses.

|

Tremendous hardness and scratch resistance (#0000 steel wool test up to

200 grams scratch resistance, pass European

K Mark

- resistance against fine particles) |

|

Perfect to be applied to

polycarbonate, nylon substrates with strong binding efficiency |

|

Excellent optical performance with refraction index higher than 1.53 and over 92% light transmission |

|

Excellent heat stable and non-yellowing to the substrates |

|

It is hard yet flexible enough to be bended during the processing steps |

|

The coated lenses are flexible and non-brittle and can pass both EC and US impact resistance safety codes |

|

The dual coating technology with the scratch resistant coating outside and anti-fog/condensation coating inside the lenses enhances product values tremendously on the coated products. |

|

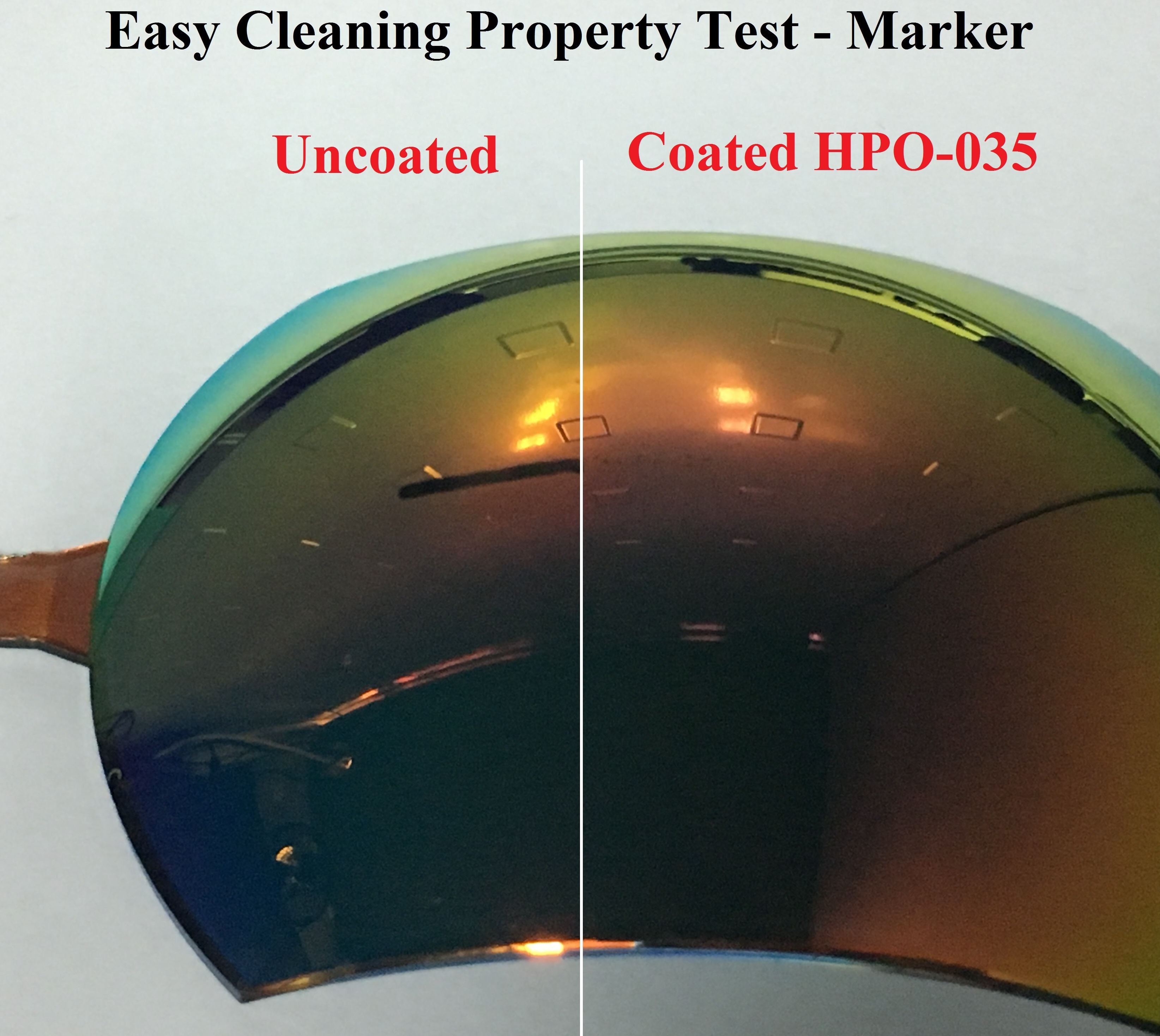

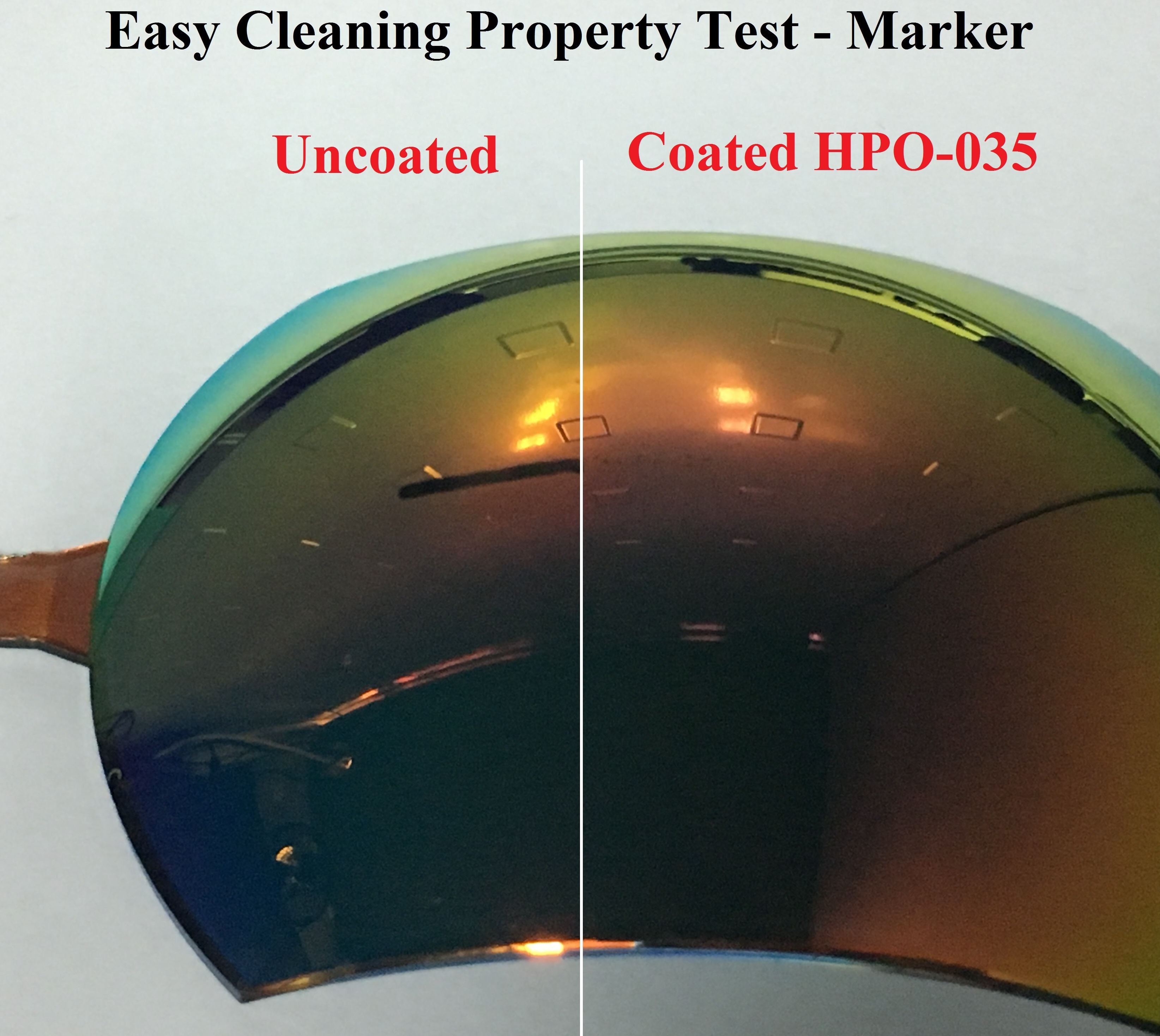

Hydrophobic Easy Cleaning Coating

HPO-036

(Applied to Hard coating and Mirror

coating substrates)

|

1.

Applied by dipping,

spraying or flow

coating.

It is easy to operate.

2.

One component system to

save both the capital

cost and operation cost.

3.

High transparency.

4.

Excellent hydrophobicity

and oleo-phobicity.

5.

Can be applied after the

hard coating pre-curing

step and cured with the

hard coating

together to

simplify

the

application

process and save cost.

|

|

HPO-027T25

(Applied to Glass substrate)

|

1.

Applied by dip, spray or

flow coat, easy to

operate.

2.

One component system to

save the capital cost of

operation.

3.

High transparency.

4. Excellent

hydrophobicity and

oleophobicity. The

contact angle reaches

about 105°

for

water

and 70° for

cooking oil.

5.

Provides scratch

resistance property to

the surface.

6.

Environmental friendly,

the solvent system is

comprised of water and

alcohols.

|

Hydrophobic Drag Reduction Coating

HDR-288

|

Super-hydrophobic antifouling coating technology |

|

High water contact angle |

|

Low sliding angle |

|

Excellent drag reduction and speed increase for fast moving boats, ships, yachts, torpedoes that travel at high turbulent flow regions |

|

Excellent antifouling capability prevents sea mollusk and shells from growing on the ship bottom |

|

Tremendous energy/oil saving for high speed water vehicles |

|

UV Type Anti-fog

Coating

UVAF-TU-9B

GELWELL UVAF-TU-9B is a super-hydrophilic

anti-fog coating designed for

PC (polycarbonate) substrate. The UVAF-TU-9B anti-fog

coating provides the anti-fog

and scratch resistance performance and

passes the EN 168, resistance against

fog, N mark.

|

Pass the

EN 168 N-Mark.

|

|

One component system

is easy to operate for

consistent high quality

output that increases

throughput and reduces

capital, labor, utility

and operational costs

|

UV Type Permanent

Anti-fog Coating

UVAF-NS-3S

GELWELL UVAF-NS-3S

which is performed permanent

anti-fog coating is applied to

PC

or

PET

substrates.

Designed for water proof anti-fog

performance for safety spectacles,

motorcycle visors, protective mask,

optical lenses, ski visors, and specific

transparent curtains, etc.

|

1.

Pass the

EN 168 N-Mark

&

ASTM-659

2.

Pass the

EN

166 K-Mark

3.

One component system

and UV curing is easy to

operate for consistent

high quality output that

increases throughput

and reduces capital,

labor, utility and

operational costs。

4.

Permanent

anti-fog performance

: Steam test under

50 oC can be

sustainable after

long-term usage.

5. No

fog

under -18 oC

freezing test.

|

TOP

TOP |

|