| Gelwell

is specializing in hydrophilic coating and hydrophobic coating

technologies. ¡@Our proprietary formulations and processing techniques

offer you the best and most cost effective solutions to meet even

the most demanding commercialization challenges and targets. Hydrophilic Coating

|

||||||||||

Gelwell's hydrophilic coating technology is applied in the anti-fog coating and slow moving water vehicle lubricious coating. Anti-fog Coating The state-of-the-art Gelwell hydrophilic anti-fog coating technology is the result of years of research and proven in the field.¡@ Tens of thousands dozens of safety lenses sold globally are coated with Gelwell anti-fog coatings every month. ¡@Besides excellent anti-fog capability, Gelwell coatings also offer excellent scratch, impact and chemical resistances. ¡@The coating solutions have low viscosity with long durability and are very stable during operation. ¡@They are easy to operate in various dipping, flow coat, spin and spray coating processes. ¡@The coating has strong binding efficiency on wide range of substrates such as polycarbonate, nylon, acrylate and glass, etc.¡@ They can be applied on safety goggles, face shields, helmet visors, snow-board visors, etc.¡@ Gelwell coatings are heat stable and non-yellowing to the substrates.¡@ They can be electroplated or tinted with beautiful colors to enhance the stylish lenses. ¡@The coated lenses are flexible and non-brittle and can pass both EC and US impact resistance safety codes. ¡@They can be bended during the lens processing steps.¡@ The Gelwell coatings have excellent optical properties with refraction index higher than 1.51 and the light transmission over 91%. ¡@Gelwell coatings are non-toxic. ¡@The major components of the Gelwell anti-fog/condensation coatings are biocompatible. Lubricious Coating for Slow Moving Water Vehicles The slow moving water vehicle lubricious coating reduces water friction around 7 - 14% depends on the size and speed of the water vehicle. ¡@At the laminar flow region (or boat speed less than a few knots), the lubricious coating is excellent in water vehicle speed acceleration and maneuvering. ¡@The coating helps many athletes won awards in the sail boat, water ski and surfing contests in the US, Asia, Australia and New Zealand. |

||||||||||

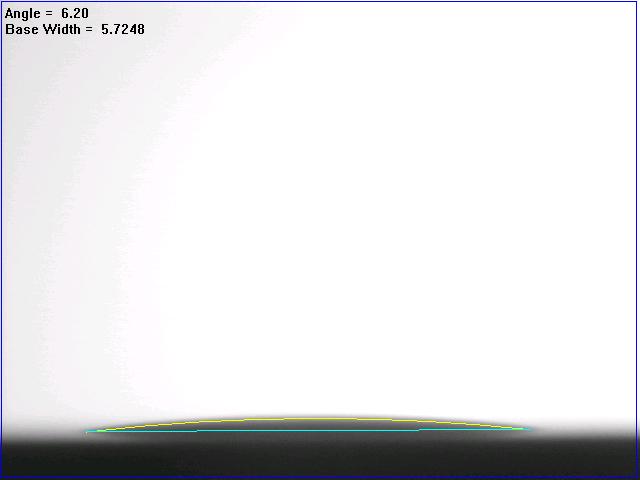

Gelwell's hydrophobic coating technology is applied in the scratch resistant coating, antifouling coating and high speed water vehicle lubricious coating. Scratch Resistant Coating Gelwell offers a variety of scratch resistant coating technologies to meet a multitude of applications that are second to none in performance and longevity.¡@ The dual coating technology with the scratch resistant coating outside and anti-fog/condensation coating inside the lenses/goggles/shields enhances product values tremendously on the coated products. ¡@The scratch resistant coating and anti-fog coating has strong binding with each other. ¡@In other words, one can apply dip coating of scratch resistant coating on both sides of lenses followed by the spraying of anti-fog coating on the inside of the lenses.¡@ The technology increases the productivity tremendously. ¡@The scratch resistant coating has strong binding efficiency on polycarbonate, nylon, acrylate substrates. ¡@It has refraction index higher than 1.51 with over 91% light transmission.¡@ It is heat stable and non-yellowing to the substrates. ¡@They can be electroplated or tinted with beautiful colors to enhance the stylish lenses. ¡@The coated lenses are flexible and non-brittle and can pass both EC and US impact resistance safety codes.¡@ They can be bended during the processing steps.¡@The coated lenses can also be recycled without darkening the virgin material. Anti-fouling Coating The super-hydrophobic antifouling coating technology can be applied to the polycarbonate, nylon, polarized and other plastic substrates.¡@ They can be used in the self cleaning lenses, visors, goggles, automobile lamps and windshields. ¡@The antifouling coating can be both hydrophobic and lipophobic to prevent fingerprint from depositing on lenses. Lubricious Coating for High Speed Moving Vehicle The super-hydrophobic antifouling coating technology can also be applied on the fast moving water vehicle for speed enhancement. ¡@The high water contact angle surface treatment results in faster speed for boats, ships, yachts, torpedoes that travel under water at high turbulent flow regions. ¡@The antifouling coating also prevents sea mollusk and shells from growing on the ship bottom. |

||||||||||

| ¡@ | ||||||||||